Welcome to Nord

Aeration Unloading System

Product Display

Aeration Unloading System

The unloading of steel silo is the top priority and difficulty of the entire silo system.

The material unloading should be divided into different zone, and the unloading should be automatically controlled. The degree of automation should be high, and the discharge speed can be adjusted. It can be freely switched between local manual, local automatic, and remote control (in the central control room) to, ensure stable and uniform discharge in the silo, prevent low discharge rate, and avoid tilting or inverted phenomena.

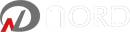

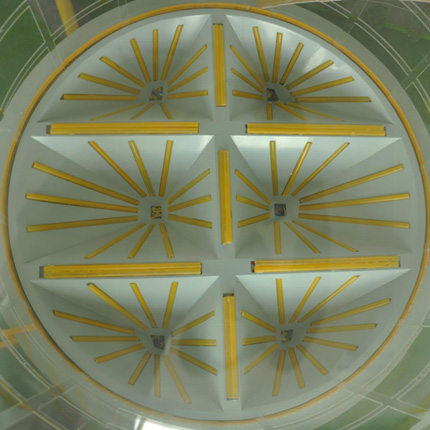

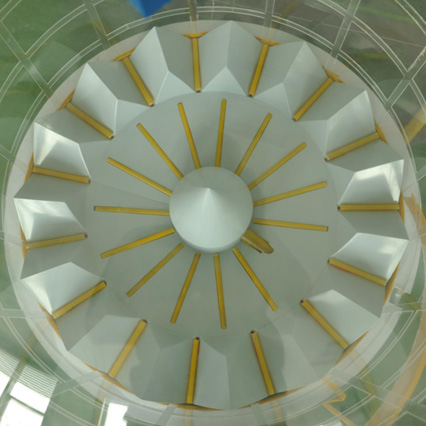

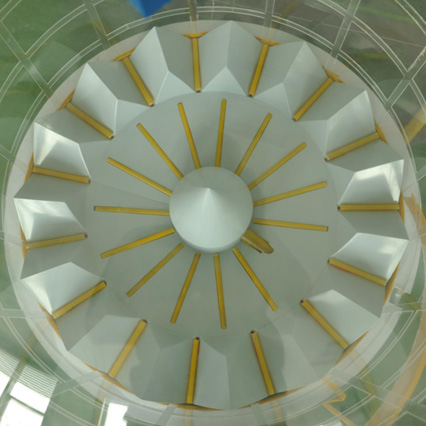

The number of fluidization rods and inflation pipelines for the bottom inflation plate of the silo is reasonably arranged according to the diameter of the silo body. There are some gallery at the bottom of the silo, and conveying equipment is installed inside the gallery. Under the gasification effect of the fluidization rods, the materials in the silo are unloaded from the discharge port to the conveying equipment inside the gallery and transported outside the silo.

The Aeration Unloading System is a remarkable innovation in the field of material handling. This system enables efficient and safe unloading of materials from silos or storage bins without any manual intervention. The process involves injecting air into the storage container, which creates an upward flow of material that evenly distributes along the discharge area and exits through an outlet at a controlled rate.

Classification

According to material characters and steel silo diameter, mainly adopts below 4 type aeration unloading method:

1.Patent unloading technology: flat slab foundation unloading technology

2.Multi unloading holes and multi gallery unloading technology

3.Multi unloading holes and single gallery unloading technology

4.Center unloading technology, main gravity unloading and assisted by aeration system unloading technology