Welcome to Nord

Galvanized Spiral Silo

Product Display

Galvanized Spiral Silo

Nord introduced German technology, develops it and widely used in projects.

Single silo capacity can be 500~8000m3, at the same time, a larger capacity steel silo group can be constructed.

Mainly used to store liquid, granular and powder materials, such as cement, fly ash, slag powder, limestone powder, oil, and grain etc. According to the site and owner requirements, multi-silo group layout can be achieved.

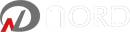

Unique construction method

Using professional spiral machine, during construction, 495mm wide galvanized coiled sheet is sent from the uncoiling machine to the forming machine and rolled into the desired geometric shape, which is then bent and bitten by the bending machine. A spiral convex strip with a width of 30mm-40mm and continuous surrounding is formed on the outside of the silo, which also plays a role in strengthening the silo.

Advantages Of Galvanized Spiral Silo:

- 01 Constructed by 275g/m2 (or higher galvanization) hot galvanized steel plates, perfect anti-corrosion performance.

- 02 Perfect sealing performance since 5 times steel bending and further sealed by sealant.

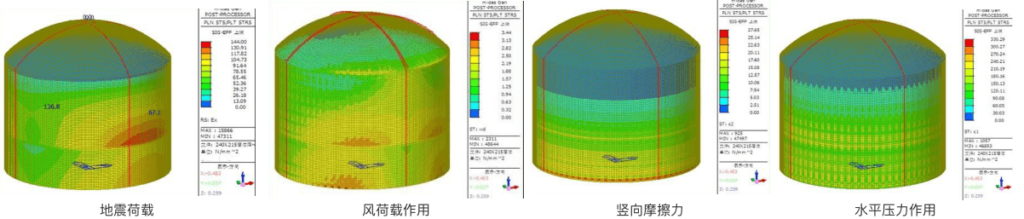

- 03 Self-weight is smaller, lower investment for silo and foundation.

- 04 Mechanical installation, short construction period.

- 05 The overall performance of the spiral silo is good, with less maintenance in operation.

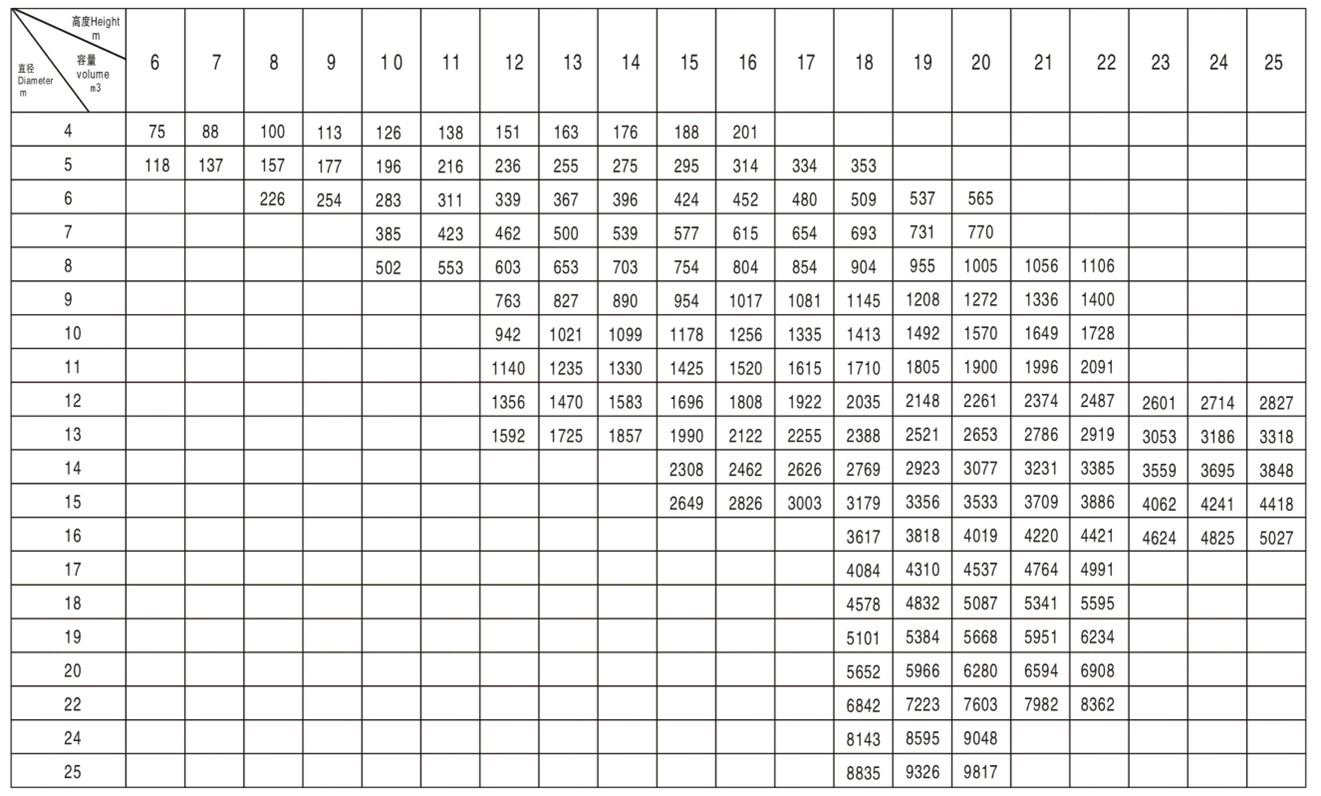

Technical Parameter

Technical Selection Table