Welcome to Nord

Dust Filter

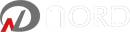

Product Display

Dust Filter

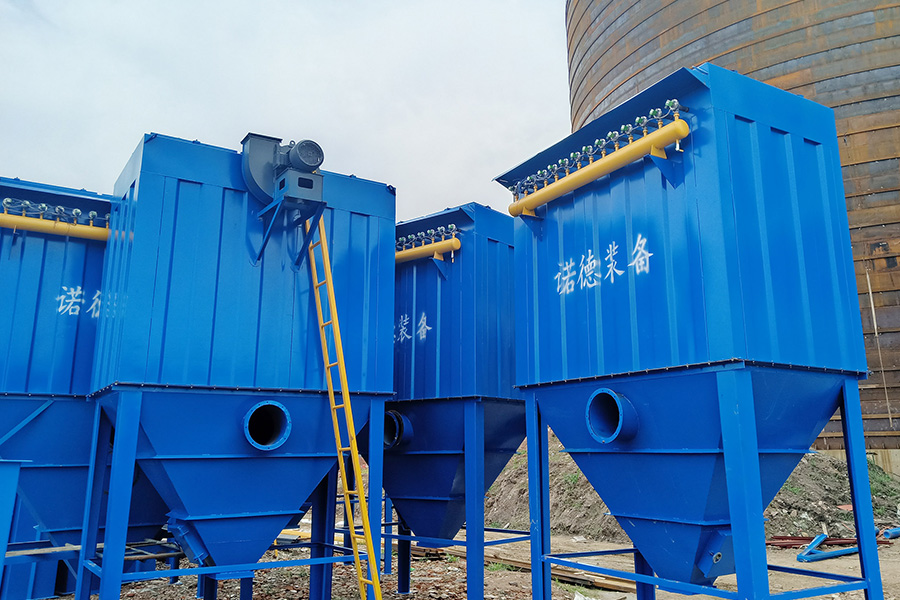

The HMC pulse single bag dust collector adopts a pulse jet cleaning method, which has the advantages of good cleaning effect, high purification efficiency, large processing air volume, long filter bag life, small maintenance workload, and safe and reliable operation.

Widely used in various operating conditions such as metallurgy, building materials, machinery, chemical industry, and mining, for the dust removal and purification of non fibrous industrial dust and material recovery in enterprises.

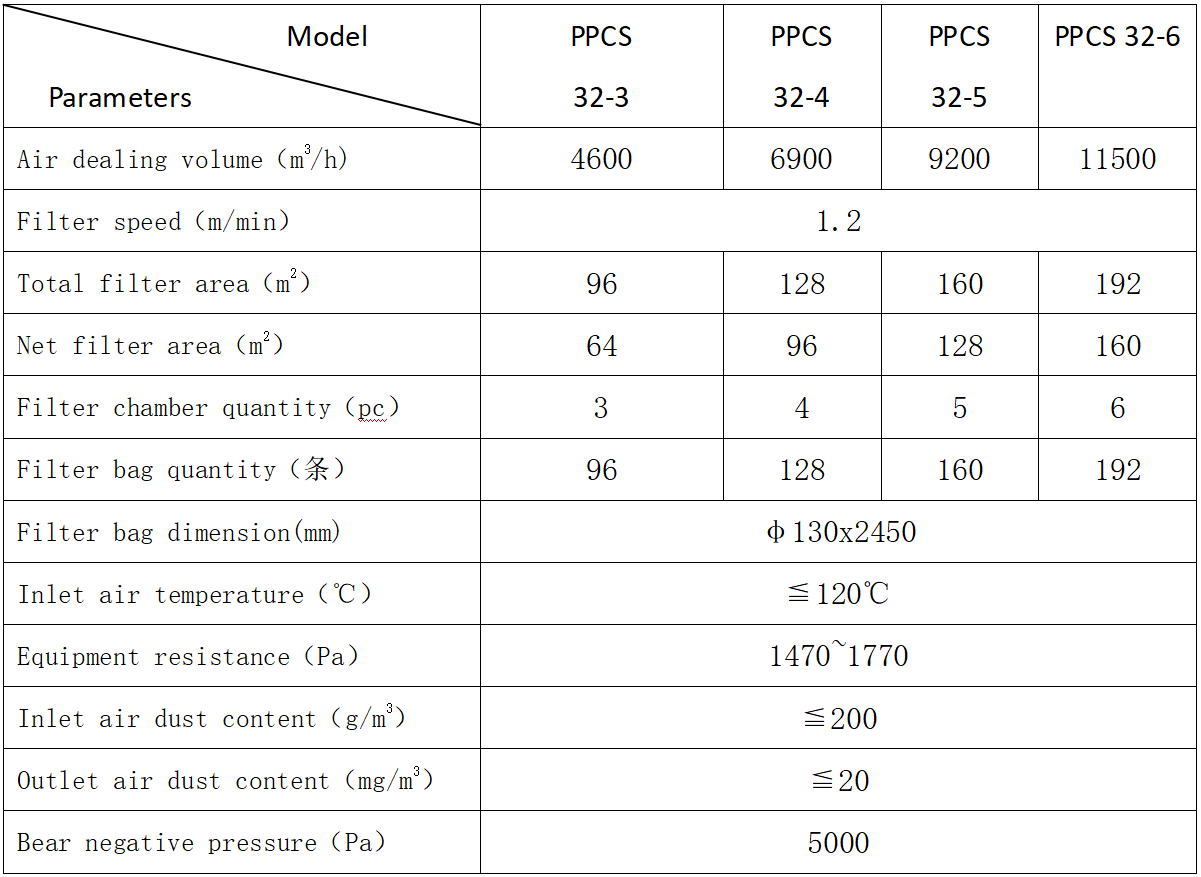

Technical Parameters Of HMC Dust Filter.

Larger Air Dealing Volume Dust Filter Can Be Multi-chamber Type

The PPCS air chamber pulse dust filter is an outdoor type consisting of various specifications with different number of chambers and filter bags. It can be widely used in crushing, packaging, silo top, clinker cooler, various mills and other dust collection systems in cement plants. If used for dust collection in coal mills, additional measures should be taken to prevent combustion and explosion, and the structure of the dust filter should also be changed accordingly. It is also suitable for dust collection of gases with extremely high dust concentration. The grinding system with O-Sepa powder concentrator in cement industry, but also for dust collection of waste gases from metallurgy, chemical industry, machinery, and civil boilers. The filter bag material of this series of dust collectors is generally made of polyester needle felt, which allows continuous use at temperatures less than 120 ℃. If the temperature increases, other filter materials should be chosen, or cooling measures should be taken before the exhaust gas enters the dust filter.

Technical Parameters Of PPCS32 Multi-chamber dust filter