Welcome to Nord

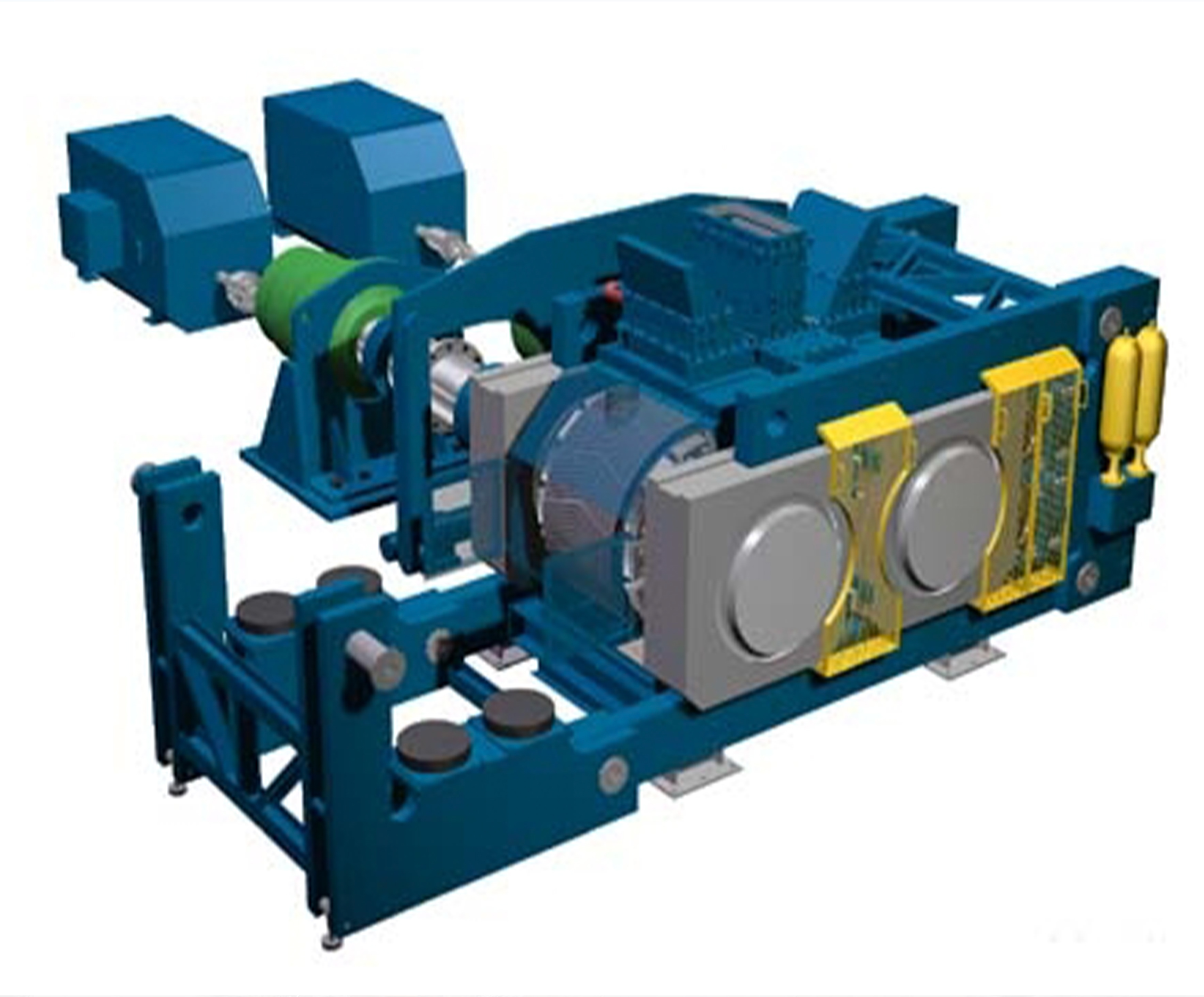

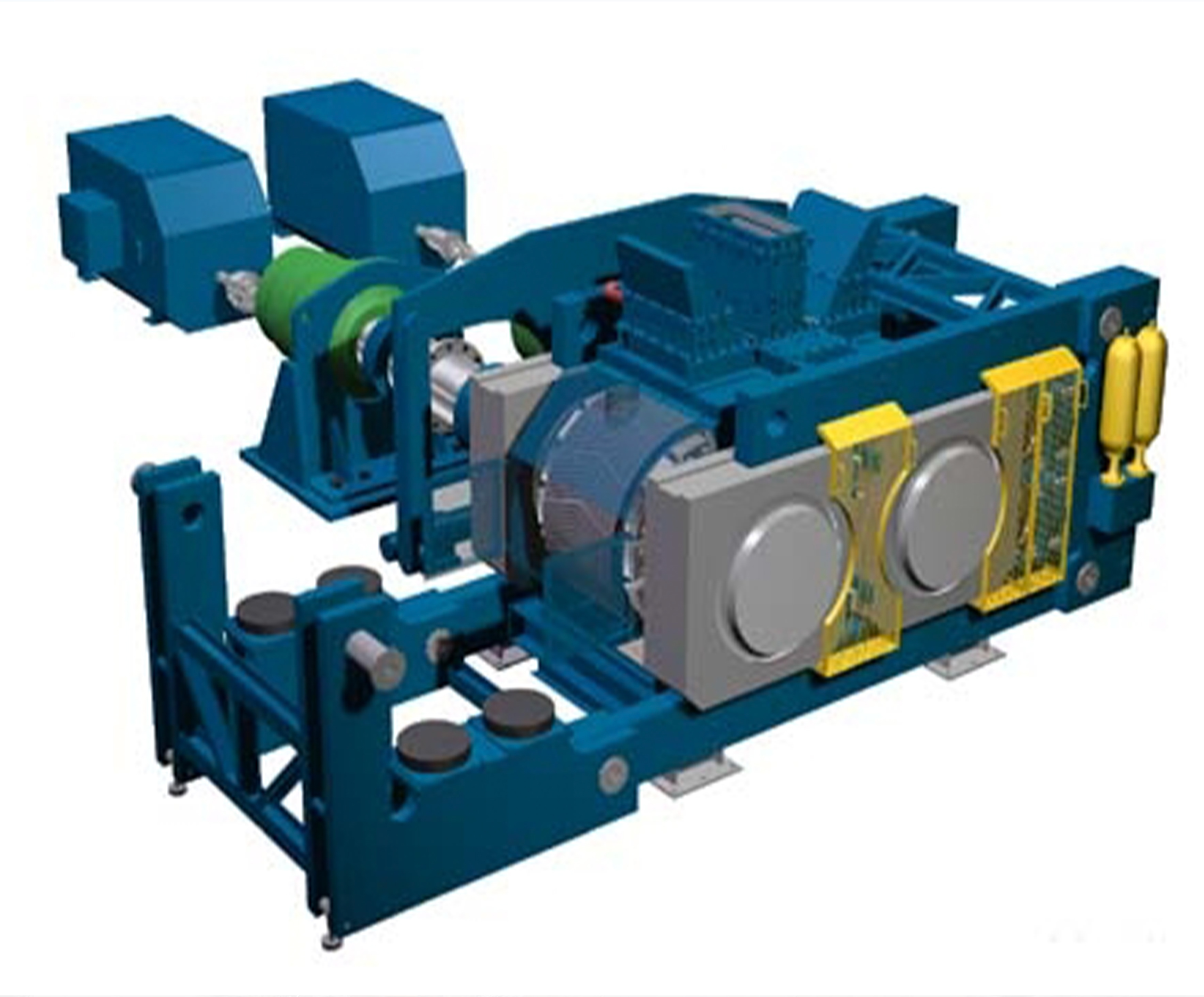

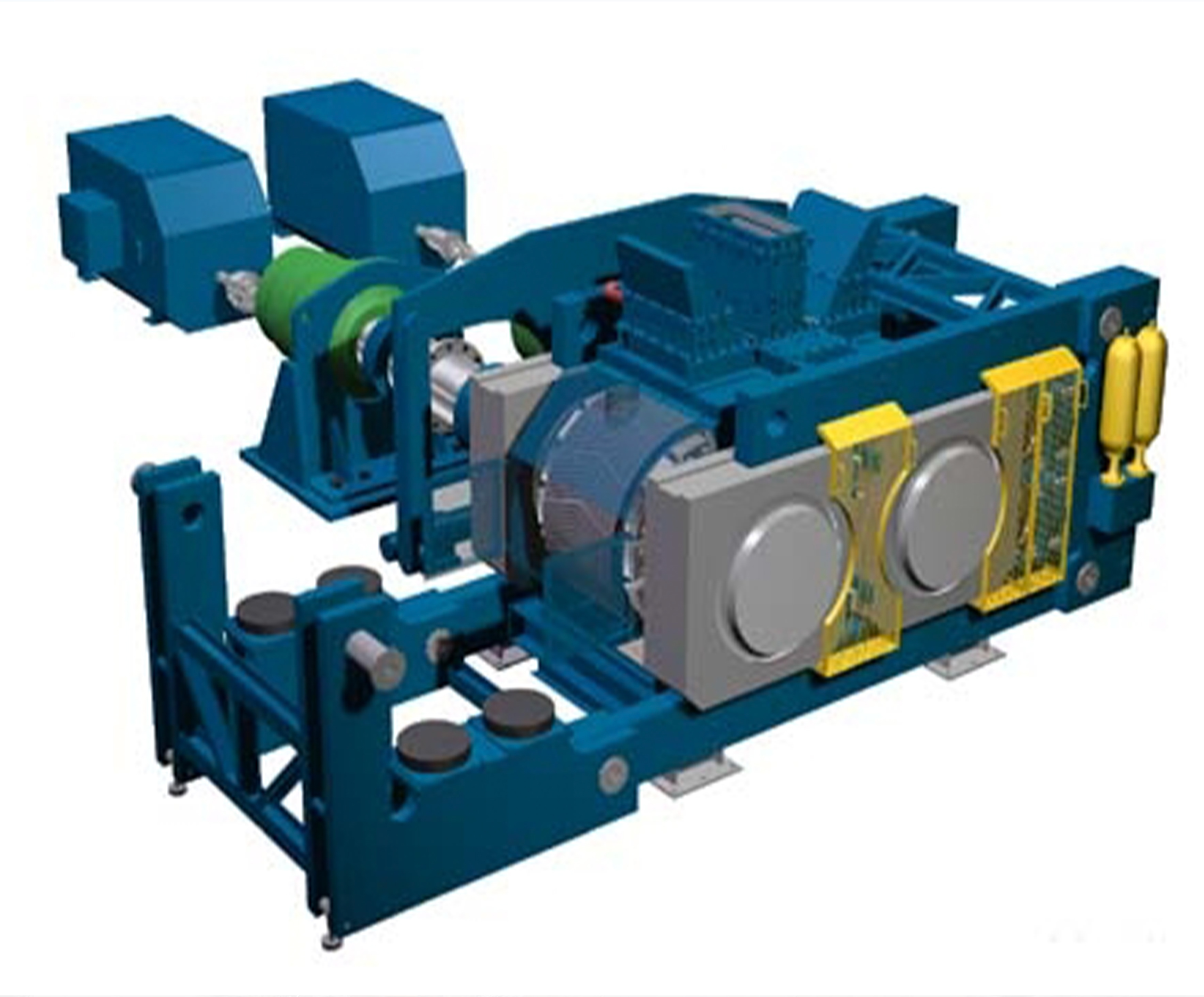

Press Roller

Product Display

Press Roller

CLF series roller press is mainly composed of motor, planetary reducer, roller system, frame, torque bearing, hydraulic pressure device, lubrication device, feeding device, roller cover, control system, etc. The two rollers are respectively driven by the motor through the universal coupling and the planetary reducer. The planetary reducer is mounted on the torque bearing and connected to the roller with a tightening disc. The roller system is divided into active roller system and fixed roller system, the two roller systems are installed on the frame, the active roller system can make horizontal movement on the frame guide rail, there are two (or four) parallel hydraulic cylinders at both ends of the active roller system to exert pressure on the bearing seat, the pressure through the roller system acts on the material between the two rollers, so that the material is broken, ground, and finally pressed into cake. The roller shaft is made of high strength forged steel, and the outer circle of the roller is surfacing with wear-resistant alloy to ensure the economic life of the roller. The hydraulic system consists of hydraulic cylinder, hydraulic station, accumulator, valve and so on. Roller clearance, cylinder pressure, bearing temperature, reducer temperature, etc. are monitored by sensors, and equipped with specially designed automatic control system.

Technical Parameters

1.CLF170100 roller press material feeding

Materials: clinker/gypsum/slag or other mixed materials

Material temperature: ≤100℃

Quartz content: < 1.5%

Humidity: ≤5%

Bulk density: -1.6t/m3

Particle size (range) : 95%≤45mm/max≤75mm

2.CLF170100 roller press output

Cake thickness (average) : about 40mm

The proportion of cake: ~ 2.3t /m3

3.CLF170100 press roller operation parameters

Capacity: 458~623t/h

Line speed: 1.58m/s

Driving power: 2×900KW

Overall roll thrust: 11900KN (Max)

Hydraulic system

Preload pressure: 7.3MPa

Working pressure: 8.5~11MPa

Nitrogen pressure: 5.1~ 6.5MPa

Working gap between rollers: 25~50mm

Initial gap between rollers: pre-adjusted to 10mm

The above data is indicative only and will be optimized during the trial run.

Other capacity roller press requirements please contact us directly.