Welcome to Nord

Grinding Plant EPC

Construction and technical renovation of the grinding station.

On the premise of ensuring stable production and reliable technology, the newly built clinker grinding station production line will achieve an ideal production line with advanced and reliable technology, advanced equipment, excellent product quality, energy conservation, high comprehensive resource utilization rate, and fully compliant environmental protection, greatly improving the competitiveness of the enterprise.

The construction of a clinker grinding station generally includes the following parts:

Raw material supply and storage

Clinker storage and transportation

Raw material batching and transportation

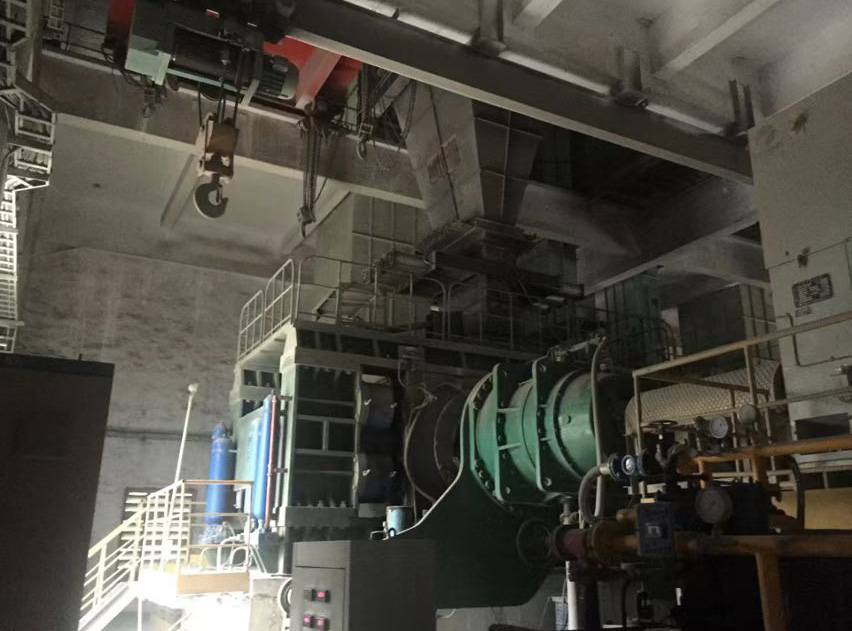

Cement grinding

Cement storage, packaging, and bulk loading

Air compressor station

The proposed project fully utilizes idle land, while meeting the engineering requirements for production, transportation, and loading and unloading. It also fully utilizes the terrain and geological conditions, closely combines the terrain to reduce the amount of earthwork, and tries to arrange main plant such as cement mills and cement silos in excavation areas with good engineering geology, creating favorable conditions for production line construction and transportation. Pay attention to wind direction and orientation to reduce environmental pollution.

Product Display